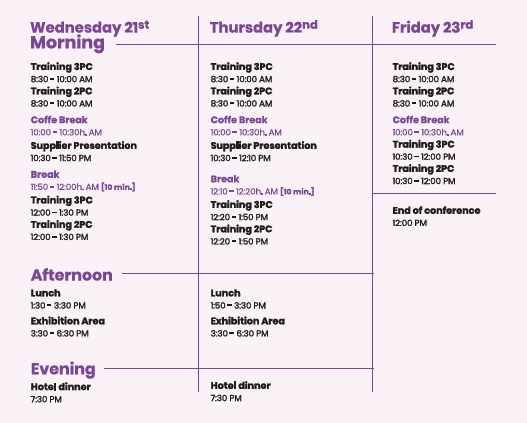

Wednesday:

Fit for purpose cans

How to qualify cans and ends for the market. What are the main

parameters manufactured cans and ends have to meet. Standard

and specific tests methodologies.

Thursday:

Specific customer requirements

What specific can and beverage parameter are of importance.

Role of beverage compatibility testing. Specific customer test

requirements.

Friday:

Management of failing cans

How to do root cause analysis of cans failing in the market. Sampling

of cans and analytical capabilities and expertise to solve issues.

Wednesday:

Quality defects and their possible solutions.

Identify and solve common quality defects in 3-piece food cans. Learn root causes, troubleshooting, and corrective actions to improve consistency and quality compliance.

CanMaking 101

An introduction to 3-piece can manufacturing. Learn materials, processes, assembly, sealing, and inspection fundamentals for reliable production

Thursday

Can welding - (challenges and best practice requirements)

Understand welding challenges and best practices for 3-piece cans. Learn how to prevent defects and ensure strong, reliable welds.

Double Seam Appreciation

Learn how to inspect and evaluate double seams to ensure hermetic sealing, product safety, and production reliability.

Friday:

Lacquer and compound application - (challenges and best practice requirements)

Master lacquer and compound application techniques to prevent defects and achieve consistent, high-quality coatings.

CI and Lean Tools "IRL"

Apply Continuous Improvement and Lean tools in real canmaking environments to reduce waste, improve efficiency, and boost quality.

Explore the latest innovations and solutions in canmaking at our exhibitor tables. Connect with industry-leading suppliers, discover new technologies and materials, and find opportunities to improve your manufacturing process.

Supplier companies will have the opportunity to showcase their latest innovations to the visitors of the fair. This platform allows businesses to highlight their unique products and services directly to potential clients, fostering valuable connections and generating business opportunities. Presenting at the fair provides an excellent occasion to interact with a targeted audience, receive immediate feedback, and increase brand visibility in a competitive market.

Eating together at the fair promotes informal networking, the exchange of ideas, the strengthening of relationships and the necessary relaxation to optimize the event experience, benefiting all participants.

Wednesday: 7:30PM dinner at hotel.

Thursday: 7:30 Welcome dinner and experience at the hotel.

You can't miss this one-of-a-kind event! Join us for an unparalleled experience full of learning, connections and exciting opportunities in the canmaking industry. Buy your ticket now and secure your spot at this must-attend event!

Explore the Future of Canmaking!